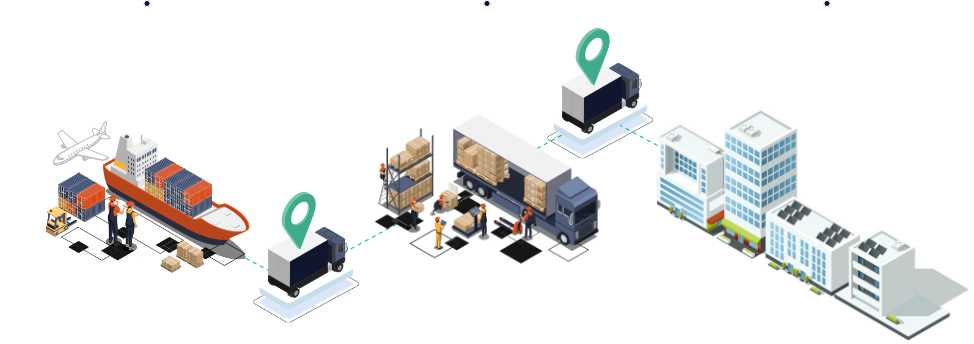

Understand how the Stark 4PL healthcare solutions work

CUSTOMER

STARK 4PL INTEGRATED SOLUTIONS

1. SOURCE

2. OPERATOR

3. DESTINATION

Well-structured and with bundled expertise, it is an integrating entity with a holistic view, providing resources and synergistic solutions among different operations.

What advantages your company get for using the Control Tower:

In this solution, we seek synergies in shared structures supported by RPA solutions, in order to automate manual processes, allowing the Procurement sector to focus on more strategic issues.

What we make possible:

One of the main pain points of the healthcare industry is managing consigned products, whether the products are in hospitals, laboratories, or home care. The management of consigned products involves IoT solutions, which eliminate this issue.

The main solutions offered for the management of consigned products are:

This AI solution was designed to address difficulties that some companies have with manual and constant processes.

The main solutions offered are:

This project breaks another paradigm in the supply chain, whether alone or along with the Outposts project.

The main advantages are:

This solution includes several optimizations in the hospital logistics management process, which results in assistance gains, reduced costs, and improved inventory management.

What advantages your company get for using the Automation:

The outposts represent a paradigm break in the current process, as they consider small operations in a strategic locations to better meet regional demands (within 48 hours).

What your company can expect after implementing this solution:

The aim is to give the customer a complete view of the distribution from the moment that the order is placed with the logistics operator, as well as better inventory management through the RFID system.

What your company gets for using the Project: